We know ERP for Food.

At Dialog, we know food. No matter your end-product, the complex challenges of the food industry require more than just generic solutions. Our tailored food enterprise resource planning (ERP) systems are ready to help you conquer this complexity.

Why You Need a Specialised Food ERP

No matter what type of food you’re producing, manufacturing, processing or delivering, your operation is complex and intricate. Changing consumer trends, product developments, evolving regulations, traceability concerns, food safety management—your list of challenges can seem never-ending. With so much at stake, a generic ERP just won’t cut it. Even with customizations, plug-ins or add-ons, you’re unlikely to get all of the capabilities you need to conquer the complexity and efficiently grow your business.

Instead, you need a tailored ERP for food from a provider that knows your industry inside out. With a tailored solution, you can unlock automation, increase efficiency, enhance visibility and maximize performance in your operation—so you can deliver quality food and meet customer demand easily.

Dialog partners with Aptean’s Food ERP solution, designed for your industry and meets Australian food traceability and safety requirements. With all the specialised capabilities and functionalities that your food manufacturing business needs, some key features you can take advantage of:

- Production Planning and Scheduling, production workstreams and routing

- End-to-end visibility into your production processes and functionality, including shop floor management and costing

- Recipe and formula features that allow for experimentation with new product lines

- Prevent cross-contamination and effectively track allergens through your entire facility

- Set up mandatory quality audits and scoresheets at every step of the production cycle

- Traceability with automated capture of data down to the granular detail

- Comprehensive Compliance documentation tracking, with automatically scheduled checks and internal audits

- Robust inventory management functions that ensure you have what you need and make the most of it

Detailed Track and Trace Capabilities

Considering just how crucial food safety is today, detailed tracking and tracing up and down your supply chains is indispensable. If you’re shopping for an ERP system, robust functionality in this area should be a requirement for any vendors you consid

Lot Tracking

Your business needs more information beyond just the lot number for where your products are located—your employees need to be able to determine what ingredients are added to your recipes, the quantities used and what point in the process they become involved. This is especially important if your products involve any allergens. Those ingredients need to be tracked during storage and handling, use, planning and tracking to make sure your bases are covered in the event of a recall. This data will also inform your cleaning processes, which warrant special attention in these instances. Having a purpose-built ERP in place will ensure that you can isolate any potential issues and immediately begin the process of rectifying mistakes in the production process.

Expiration Date

Sound management of your products based on expiration dates is critical not only for food safety reasons, but also to protect the investments you’ve made in your raw materials. How can you make sure you’re on top of your timeframes and picking ingredients based on a first expiry, first out (FEFO) basis? Again, the ideal ERP solution will have tools for this very purpose built in and will alert your team in case of issues.

Managing Quality

Both regulatory compliance and customer service hinge on good quality assurance checks, and the best ERP systems facilitate these through automation, integration with smart sensors and complete visibility of your data.

Recipe Control

Because your business likely purchases materials in bulk—by the kilogram, bag, case, etc.—your systems need to be able to perform accurate conversions reliably. You also need complete control over the variables associated with these materials, like consistency, acidity and more. The technology of ERP solutions allows you to dial in with great precision on the aspects of your products that matter the most. They can also alert your team in the case of parameters falling out of your desired ranges

Accounting for Yield

Your production processes’ yield levels are likely among the most closely watched metrics that you deal with, and your ERP should be able to give you precise, up-to-date insight into these numbers. The system should also be able to account for inevitable losses due to evaporation or materials sticking to containers and mixing vessels. Getting these measures right will have an impact on consumer satisfaction—as well as for the efficiency of your processes—so don’t underestimate the importance of this feature

Conformance

Non-conformance logging, corrective and preventative action (CAPA) reporting and document control are also important parts of quality management, and your ERP should come packed with features to address these measures. Easy access to your data from all stages of production will be necessary when you need to determine when, why and where an error occurred. This, in turn, will help you meet both your own standards as well as those imposed by governments and regulatory bodies.

Make Financial Management Simple

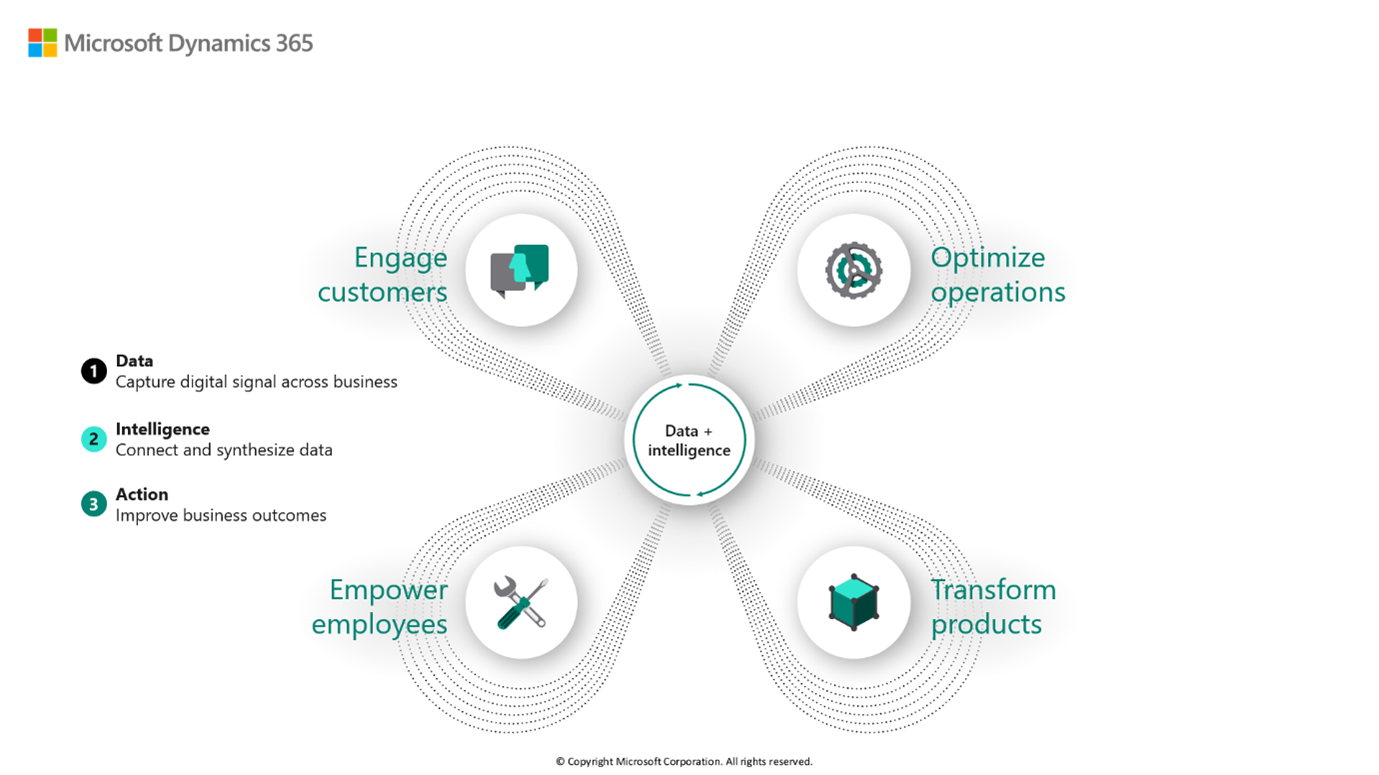

Aptean Food ERP is built on the Microsoft Business Central platform and streamlines and integrates finance within one solution. Manage all common finance processes and information such as posting financial transactions, preparing financial statements, managing bank accounts, inventory costs, manufacturing costs, budgets and fixed assets. You have one source of truth across all your business functions as data is centrally stored in the ERP.

Don’t Settle for Generic

As a food and beverage batch process manufacturer, your business can’t take shortcuts when it comes to customer satisfaction, safety and standards adherence. If you think you can rely on manual processes and information isolated in certain departments or systems, you’ll end up with unsatisfactory results.

Dialogs dedicated F&B team and Aptean Food ERP, a combination of decades of industry experience and extensive knowledge of best practices in the areas of lot traceability, recipe management, compliance and more. You’ll have complete ownership of your data and processes.

Start transforming your food business today

If you’re ready to take your operation to the next level, we’d love to help.